Introduction

ARK 400 arc spray coating is a FeCrMoCB alloy and has an amorphous and nanocrystalline structure. Sprayed layers for this wire are dense and do not have coarse pores or microcracks. ARK 400 cored wire coating bonds well to the substrate and has a high bonding strength (on average ≥55 MPa) and can be used without primer. The hardness of the coating is 840-1200 HV with an average of 1013 HV.

[Patented product: High hardness and high wear resistance arc spraying cored wire. ZL200510132112.3; electric arc spraying preparation of powder core wire ZL200610089516.3 for amorphous coating containing NiB; electric arc spraying preparation powder for CrB containing amorphous coating Core wire material ZL200610089515.9]

Main features

- Good wear resistance

- Corrosion resistance

- Good resistance to high temperature oxidation corrosion

Typical applications

- Suitable for protection of severely worn parts

- Waste incineration

- Biomass power generation

- Coal-fired power station boiler tubs

- Can replace hard chrome plating and other products

Chemical composition of deposited metal (%)

| Cr | Mo | B | Mn | Fe |

|---|---|---|---|---|

| 23.0–26.0 | 7.0–12.0 | 2.0–5.0 | 0.8–1.5 | Balance |

Mechanical properties

| Bond Strength (MPa) Acc. to ASTM C633-01 | Micro-hardness (HV 0.1, kg/mm²) |

|---|---|

| 55–57 | 840–1200 |

Coating properties

| Density (g/cm³) | % Prosity | % Deposition efficiency |

|---|---|---|

| <5 | 70–85 |

Recommended spraying parameters

| Diameter: in (mm) | Air pressure (MPa) | Current (A) | Voltage (V) |

|---|---|---|---|

| 1⁄16 (1.6) | 0.5–0.6 | 180–240 | 30–32 |

Diameters and packaging

| Diameter: in (mm) | Packaging: lb (kg) |

|---|---|

| 1⁄16 (1.6) | 27.5 (12.5) (Vacuum pack spool) |

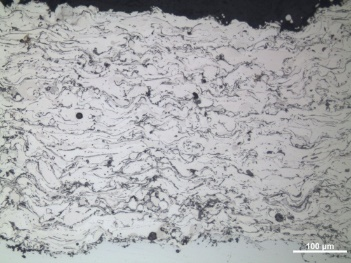

Metallographic photo

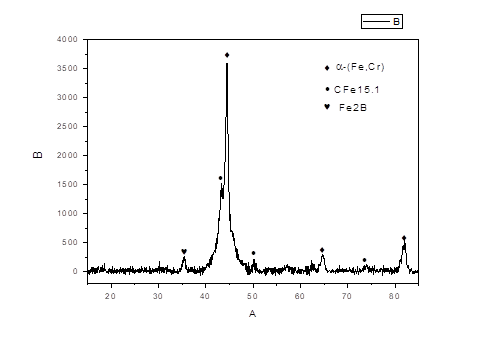

XRD results

| Click here to download the datasheet for Kooben ARK 400. |